In silico evaluation of 5 industrial microorganisms identifies optimum strains and metabolic engineering methods for producing 235 precious chemical substances.

Local weather change and the depletion of fossil fuels have raised the worldwide want for sustainable chemical manufacturing. In response to those environmental challenges, microbial cell factories are gaining consideration as eco-friendly platforms for producing chemical substances utilizing renewable assets, whereas metabolic engineering applied sciences to reinforce these cell factories have gotten essential instruments for maximizing manufacturing effectivity.

Nevertheless, difficulties in choosing appropriate microbial strains and optimizing advanced metabolic pathways proceed to pose important obstacles to sensible industrial functions.

Professor Sang Yup Lee’s analysis workforce within the Division of Chemical and Biomolecular Engineering comprehensively evaluated the manufacturing capabilities of varied industrial microbial cell factories utilizing in silico simulations and, based mostly on these findings, recognized probably the most appropriate microbial strains for producing particular chemical substances in addition to optimum metabolic engineering methods.

Beforehand, researchers tried to find out the perfect strains and environment friendly metabolic engineering methods amongst quite a few microbial candidates by means of intensive organic experiments and meticulous verification processes. Nevertheless, this strategy required substantial time and prices.

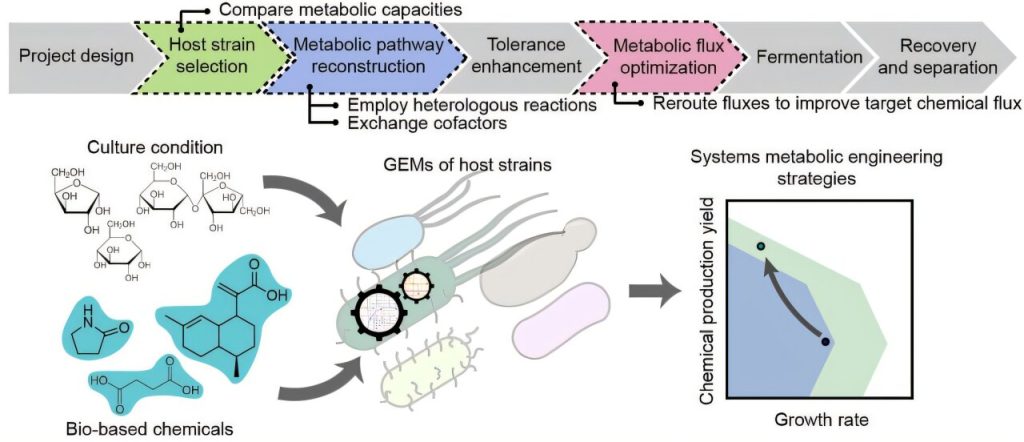

Lately, the introduction of genome-scale metabolic fashions (GEMs), which reconstruct the metabolic networks inside an organism based mostly on its complete genome info, has enabled systematic evaluation of metabolic fluxes by way of laptop simulations. This growth gives a brand new option to overcome the restrictions of typical experimental approaches, revolutionizing each pressure choice and metabolic pathway design.

Accordingly, Professor Lee’s workforce on the Division of Chemical and Biomolecular Engineering, KAIST, evaluated the manufacturing capabilities of 5 consultant industrial microorganisms—Escherichia coli, Saccharomyces cerevisiae, Bacillus subtilis, Corynebacterium glutamicum, and Pseudomonas putida—for 235 bio-based chemical substances.

Utilizing GEMs, the researchers calculated each the utmost theoretical yields and the utmost achievable yields beneath industrial situations for every chemical, thereby establishing standards to establish probably the most appropriate strains for every goal compound.

The workforce particularly proposed methods similar to introducing heterologous enzyme reactions derived from different organisms and exchanging cofactors utilized by microbes to broaden metabolic pathways. These methods had been proven to extend yields past the innate metabolic capacities of the microorganisms, leading to larger manufacturing of industrially necessary chemical substances similar to mevalonic acid, propanol, fatty acids, and isoprenoids.

Furthermore, by making use of a computational strategy to research metabolic fluxes in silico, the researchers recommended methods for bettering microbial strains to maximise the manufacturing of varied chemical substances. They quantitatively recognized the relationships between particular enzyme reactions and goal chemical manufacturing, in addition to the relationships between enzymes and metabolites, figuring out which enzyme reactions ought to be up- or down-regulated. By means of this, the workforce introduced methods not solely to attain excessive theoretical yields but additionally to maximise precise manufacturing capacities.

Dr. Gi Bae Kim, the primary writer of this paper from the KAIST BioProcess Engineering Analysis Heart, defined, “By introducing metabolic pathways derived from different organisms and exchanging cofactors, it’s doable to design new microbial cell factories that surpass current limitations. The methods introduced on this research will play a pivotal position in making microbial-based manufacturing processes extra economical and environment friendly.”

As well as, Distinguished Professor Sang Yup Lee famous, “This analysis serves as a key useful resource within the discipline of techniques metabolic engineering, decreasing difficulties in pressure choice and pathway design, and enabling extra environment friendly growth of microbial cell factories. We count on it to tremendously contribute to the longer term growth of applied sciences for producing numerous eco-friendly chemical substances, similar to biofuels, bioplastics, and practical meals supplies.”

The findings are revealed within the journal Nature Communications.

Extra info:

Gi Bae Kim et al, Complete analysis of the capacities of microbial cell factories, Nature Communications (2025). DOI: 10.1038/s41467-025-58227-1 , www.nature.com/articles/s41467-025-58227-1

Quotation:

Evaluation identifies optimum microbes for sustainable chemical manufacturing (2025, March 27)

retrieved 28 March 2025

from https://phys.org/information/2025-03-analysis-optimal-microbes-sustainable-chemical.html

This doc is topic to copyright. Other than any honest dealing for the aim of personal research or analysis, no

half could also be reproduced with out the written permission. The content material is offered for info functions solely.