Researchers have developed a delicate robotic arm able to performing advanced duties resembling navigating round an impediment or hitting a ball, guided and powered remotely by laser beams with none onboard electronics or wiring.

The analysis might inform new methods to manage implantable surgical units or industrial machines that have to deal with delicate objects.

“Our materials bends towards laser gentle like a flower stem does towards daylight.”

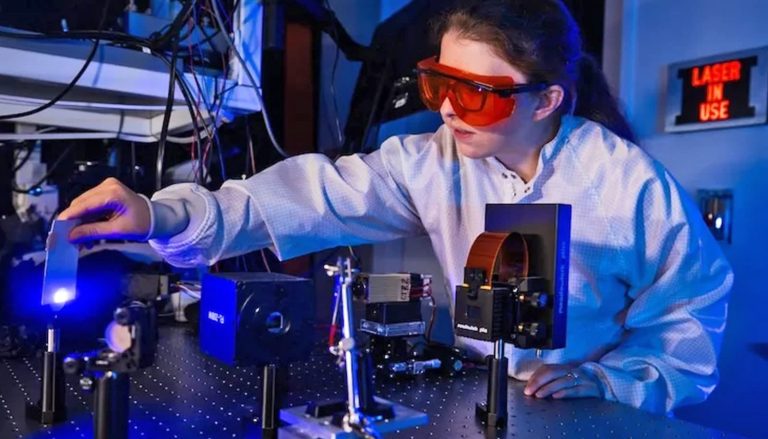

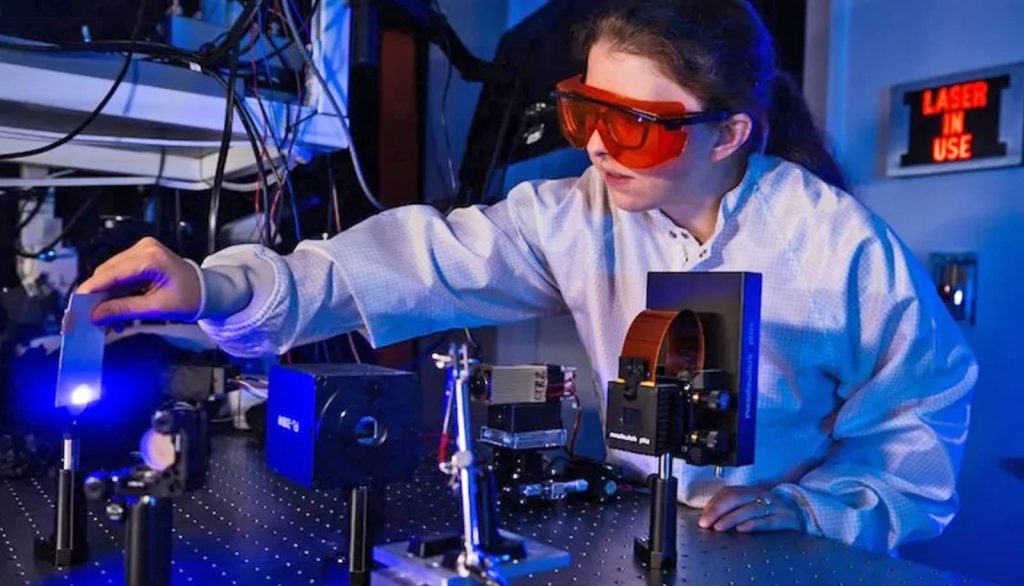

In a proof-of-concept research that integrates good supplies, machine studying, and an optical management system, a workforce of Rice College researchers led by supplies scientist Hanyu Zhu used a light-patterning machine to exactly induce movement in a robotic arm comprised of azobenzene liquid crystal elastomer—a sort of polymer that responds to gentle.

Based on the research in Superior Clever Techniques, the brand new robotic system incorporates a neural community educated to foretell the precise gentle sample wanted to create particular arm actions. This makes it simpler for the robotic to execute advanced duties without having equally advanced enter from an operator.

“This was the primary demonstration of real-time, reconfigurable, automated management over a light-responsive materials for a delicate robotic arm,” says Elizabeth Blackert, a doctoral alumna who’s the primary creator on the research.

Typical robots usually contain inflexible buildings with cell parts like hinges, wheels, or grippers to allow a predefined, comparatively constrained vary of movement. Mushy robots have opened up new areas of software in contexts like drugs, the place safely interacting with delicate objects is required. So-called continuum robots are a sort of sentimental robotic that forgoes mobility constraints, enabling adaptive movement with a vastly expanded diploma of freedom.

“A significant problem in utilizing delicate supplies for robots is they’re both tethered or have quite simple, predetermined performance,” says Zhu, assistant professor of supplies science and nanoengineering.

“Constructing remotely and arbitrarily programmable delicate robots requires a singular mix of experience involving supplies growth, optical system design, and machine studying capabilities. Our analysis workforce was uniquely suited to tackle this interdisciplinary work.”

The workforce created a brand new variation of an elastomer that shrinks beneath blue laser gentle then relaxes and regrows at midnight—a characteristic often known as quick rest time that makes real-time management potential. In contrast to different light-sensitive supplies that require dangerous ultraviolet gentle or take minutes to reset, this one works with safer, longer wavelengths and responds inside seconds.

“Once we shine a laser on one aspect of the fabric, the shrinking causes the fabric to bend in that path,” Blackert says. “Our materials bends towards laser gentle like a flower stem does towards daylight.”

To regulate the fabric, the researchers used a spatial gentle modulator to separate a single laser beam into a number of beamlets, every directed to a unique a part of the robotic arm. The beamlets could be turned on or off and adjusted in depth, permitting the arm to bend or contract at any given level, very like the tentacles of an octopus. This system can in precept create a robotic with just about infinite levels of freedom—far past the capabilities of conventional robots with fastened joints.

“What’s new right here is utilizing the sunshine sample to realize advanced modifications in form,” says Rafael Verduzco, professor and affiliate chair of chemical and biomolecular engineering and professor of supplies science and nanoengineering.

“In prior work, the fabric itself was patterned or programmed to alter form in a technique, however right here the fabric can change in a number of methods, relying on the laser beamlet sample.”

To coach such a multiparameter arm, the workforce ran a small variety of combos of sunshine settings and recorded how the robotic arm deformed in every case, utilizing the information to coach a convolutional neural community—a sort of synthetic intelligence utilized in picture recognition. The mannequin was then in a position to output the precise gentle sample wanted to create a desired form resembling flexing or a reach-around movement.

The present prototype is flat and strikes in 2D, however future variations might bend in three dimensions with extra sensors and cameras.

“This can be a step in the direction of having safer, extra succesful robotics for numerous functions starting from implantable biomedical units to industrial robots that deal with delicate items,” Blackert says.

Help for the analysis got here from the Nationwide Science Basis, the Welch Basis, and the US Military Analysis Workplace. All opinions expressed on this press launch are the authors’ and don’t essentially replicate the insurance policies and views of the funding entities.

Supply: Rice College