A brand new methodology for producing yogurt has been developed by a analysis staff on the DTU Nationwide Meals Institute, and all of it started with an easy query.

“We have studied lactic acid micro organism and their vitality metabolism for years, however in the future it struck us: what if we let the micro organism acidify with out permitting them to develop? It was one thing of a eureka second,” says Affiliate Professor Christian Solem, who has researched lactic acid micro organism for greater than 25 years.

The strategy has been examined on a smaller scale within the laboratory on the DTU Nationwide Meals Institute, and the researchers see no cause why it can’t be instantly applied by dairies. It requires no new expertise—solely an adjustment of the temperature management throughout manufacturing.

“In precept, dairies might undertake the tactic as early as tomorrow. We’ve not noticed any drawbacks, aside from the method taking an hour or two longer—and you’ll have a extra steady and sustainable product,” says Solem.

The analysis holds nice potential, as it’s estimated that, on common, every particular person globally consumes almost 12 kilograms of yogurt yearly. The analysis is revealed within the journal Meals Bioscience.

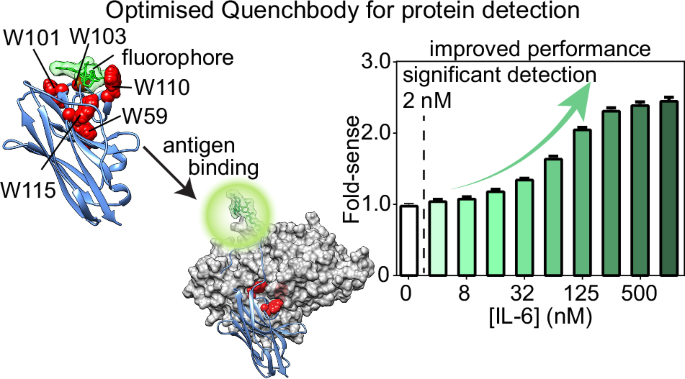

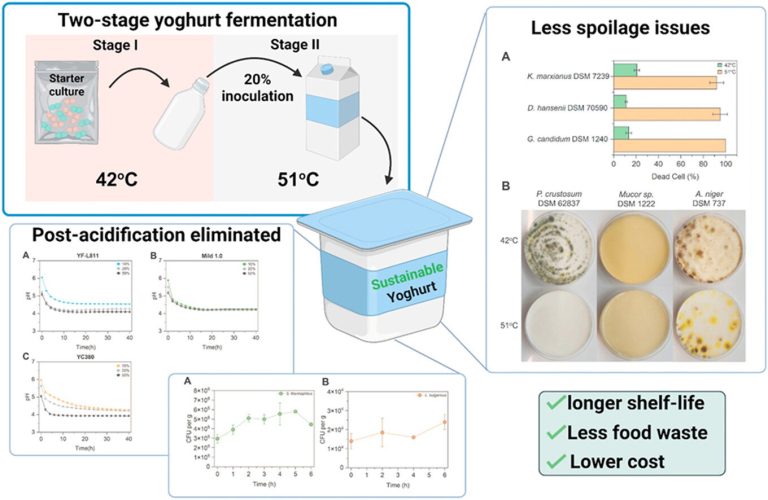

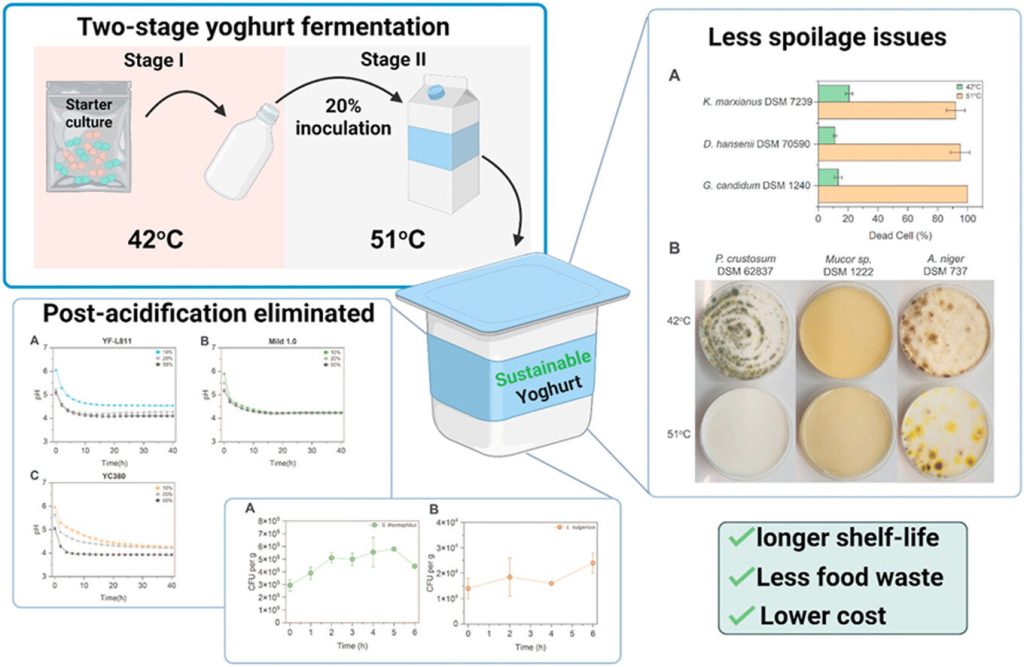

A two-step fermentation approach

Conventional yogurt manufacturing includes including a comparatively great amount of yogurt starter tradition to take advantage of, which is then fermented at 42°C for 4–6 hours. The specified acidity is then reached, and the yogurt is cooled. Nonetheless, the method is thought to current a number of challenges: excessive prices for starter tradition, restricted shelf life, and so-called “post-acidification,” the place the yogurt continues to acidify throughout storage, affecting each high quality and longevity.

With the brand new methodology, researchers use simply 20% of the same old quantity of starter tradition. The milk is first fermented at 42°C, as per normal process, after which the temperature is raised to 51°C for just a few hours. At this elevated temperature, the micro organism stop to divide, however proceed to provide lactic acid.

“It is like placing the micro organism on a treadmill—they are not going wherever, however they’re nonetheless working. This enables us to regulate the acidification whereas avoiding undesirable post-acidification,” explains Solem.

The 51°C step additionally acts virtually as a gentle pasteurization section. “We eradicate as much as 99.9% of yeast cells and mould spores, which might in any other case considerably shorten the yogurt’s shelf life,” says Solem.

Goodbye to post-acidification—good day to prolonged shelf life

Put up-acidification is among the many most severe high quality considerations in yogurt manufacturing. It causes the product to grow to be overly bitter, bitter, and susceptible to section separation—traits usually related to spoiled yogurt.

“We have examined the tactic on three totally different starter cultures, together with some significantly susceptible to post-acidification. In all instances, the problem was resolved,” says Postdoctoral Researcher Shuangqing Zhao, corresponding writer of the research.

The precise extension of shelf life has not but been decided, however in keeping with the researchers, it’s anticipated to far exceed the present 3–4 weeks. This might have vital implications for each long-distance transport and meals waste discount.

Substantial advantages for dairies

At current, dairies use as much as 0.18 grams of starter tradition per liter of milk. Given the dimensions of manufacturing, the price of bacterial cultures could be appreciable.

“We scale back using starter tradition by an element of 5. That is a considerable saving, and it issues in an business the place revenue margins are tight,” says Solem.

Furthermore, the prolonged shelf life improves planning and logistics:

“Yogurt is often produced in massive batches, and every manufacturing run requires cleansing and reconfiguration. With longer shelf life, bigger and maybe even extra steady manufacturing turns into possible,” he provides.

Extra info:

Liuyan Gu et al, Smoking sizzling – Warmth-induced uncoupling of development & acidification in yoghurt manufacturing helps save prices and ends in decreased post-acidification and improved shelf life, Meals Bioscience (2025). DOI: 10.1016/j.fbio.2025.107046

Supplied by

Technical College of Denmark

Quotation:

Easy yogurt manufacturing tweak cuts bacterial tradition prices and extends shelf life (2025, June 19)

retrieved 19 June 2025

from https://phys.org/information/2025-06-simple-yogurt-production-tweak-bacterial.html

This doc is topic to copyright. Other than any truthful dealing for the aim of personal research or analysis, no

half could also be reproduced with out the written permission. The content material is offered for info functions solely.