Plastics – the quick Information 2023 (Plastics Europe, 2023).

Geyer, R., Jambeck, J. R. & Regulation, Ok. L. Manufacturing, use, and destiny of all plastics ever made. Sci. Adv. 3, 25–29 (2017).

MacLeod, M., Arp, H. P. H., Tekman, M. B. & Jahnke, A. The worldwide menace from plastic air pollution. Science 373, 61–65 (2021).

Mitrano, D. M., Wick, P. & Nowack, B. Putting nanoplastics within the context of worldwide plastic air pollution. Nat. Nanotechnol. 16, 491–500 (2021).

Vethaak, A. D. & Legler, J. Microplastics and human well being. Science 371, 672–674 (2021).

Sheng, D. et al. Plastic air pollution in agricultural landscapes: an ignored menace to pollination, biocontrol and meals safety. Nat. Commun. 15, 8413 (2024).

Wei, R. & Zimmermann, W. Microbial enzymes for the recycling of recalcitrant petroleum-based plastics: how far are we? Microb. Biotechnol. 10, 1308–1322 (2017).

Singh, A. et al. Techno-economic, life-cycle, and socioeconomic influence evaluation of enzymatic recycling of poly(ethylene terephthalate). Joule 5, 2479–2503 (2021).

Nicholson, S. R., Rorrer, N. A., Carpenter, A. C. & Beckham, G. T. Manufacturing power and greenhouse fuel emissions related to plastics consumption. Joule 5, 673–686 (2021).

Clark, A. R. & Shaver, M. P. Depolymerization inside a round plastics system. Chem. Rev. 124, 2617–2650 (2024).

Tournier, V. et al. Enzymes’ energy for plastics degradation. Chem. Rev. 123, 5612–5701 (2023).

Zimmermann, W. Biocatalytic recycling of polyethylene terephthalate plastic. Phil. Trans. R. Soc. A 378, 20190273 (2020).

Sonnendecker, C. et al. Low carbon footprint recycling of post-consumer PET plastic with a metagenomic polyester hydrolase. ChemSusChem 15, e202101062 (2022).

Tournier, V. et al. An engineered PET depolymerase to interrupt down and recycle plastic bottles. Nature 580, 216–219 (2020).

Lu, H. et al. Machine learning-aided engineering of hydrolases for PET depolymerization. Nature 604, 662–667 (2022).

Cheng, Y., Cheng, Y., Zhou, S., Ruzha, Y. & Yang, Y. Closed-loop recycling of PET cloth and bottle waste by tandem pre-amorphization and enzymatic hydrolysis. Resour. Conserv. Recy. 208, 107706 (2024).

Tiso, T. et al. In the direction of bio-upcycling of polyethylene terephthalate. Metab. Eng. 66, 167–178 (2021).

Jehanno, C. et al. Important advances and future alternatives in upcycling commodity polymers. Nature 603, 803–814 (2022).

Zuin, V. G. & Kümmerer, Ok. Chemistry and supplies science for a sustainable round polymeric financial system. Nat. Rev. Mater. 7, 76–78 (2022).

Bhattacharjee, S. et al. Chemoenzymatic photoreforming: a sustainable strategy for solar-fuel technology from plastic feedstocks. J. Am. Chem. Soc. 145, 20355–20364 (2023).

Zimmermann, W. & Billig, S. in Biofunctionalization of Polymers and Their Functions (eds Nyanhongo, G. et al.) 97–120 (Springer, 2011).

Marten, E., Mueller, R. J. & Deckwer, W. D. Research on the enzymatic hydrolysis of polyesters. II. Aliphatic-aromatic copolyesters. Polym. Degrad. Stab. 88, 371–381 (2005).

Müller, R. J., Schrader, H., Profe, J., Dresler, Ok. & Deckwer, W. D. Enzymatic degradation of poly (ethylene terephthalate): fast hydrolyse utilizing a hydrolase from T. fusca. Macromol. Speedy Commun. 26, 1400–1405 (2005).

Yoshida, S. et al. A bacterium that degrades and assimilates poly(ethylene terephthalate). Science 351, 1196–1199 (2016).

Han, X. et al. Structural perception into catalytic mechanism of PET hydrolase. Nat. Commun. 8, 2106 (2017).

Jerves, C., Neves, R. P. P., Da Silva, S. L., Ramos, M. J. J. & Fernandes, P. A. Charge-enhancing PETase mutations decided by DFT/MM molecular dynamics simulations. N. J. Chem. 48, 45–54 (2024).

Burgin, T. et al. The response mechanism of the Ideonella sakaiensis PETase enzyme. Commun. Chem. 7, 65 (2024).

Dos Santos, A. M., da Costa, C. H. S., Silva, P. H. A., Skaf, M. S. & Lameira, J. Exploring the response mechanism of polyethylene terephthalate biodegradation by QM/MM strategy. J. Phys. Chem. B 128, 7486–7499 (2024).

Sulaiman, S. et al. Isolation of a novel cutinase homolog with polyethylene terephthalate-degrading exercise from leaf-branch compost through the use of a metagenomic strategy. Appl. Environ. Microbiol. 78, 1556–1562 (2012).

Jäckering, A., van der Kamp, M., Strodel, B. & Zinovjev, Ok. Affect of wobbling tryptophan and mutations on PET degradation explored by QM/MM free power calculations. J. Chem. Inf. Mannequin. 64, 7544–7554 (2024).

Herzog, Ok., Müller, R.-J. & Deckwer, W.-D. Mechanism and kinetics of the enzymatic hydrolysis of polyester nanoparticles by lipases. Polym. Degrad. Stabil. 91, 2486–2498 (2006).

Frank, R., Krinke, D., Sonnendecker, C., Zimmermann, W. & Jahnke, H.-G. Actual-time, non-invasive evaluation of biocatalytic PET degradation. ACS Catal. 12, 25–35 (2022).

Bååth, J. A., Borch, Ok., Jensen, Ok., Brask, J. & Westh, P. Comparative biochemistry of 4 polyester (PET) hydrolases. ChemBioChem 22, 1627–1637 (2021).

Wei, R. et al. Turbidimetric evaluation of the enzymatic hydrolysis of polyethyleneterephthalate nanoparticles. J. Mol. Catal. B Enzym. 103, 72–78 (2014).

Heidrich, D. & Gehde, M. The three-phase construction of polyesters (PBT, PET) after isothermal and non-isothermal crystallization. Polymers 14, 793 (2022).

Ronkvist, A. M., Xie, W., Lu, W. & Gross, R. A. Cutinase-catalyzed hydrolysis of poly(ethylene terephthalate). Macromolecules 42, 5128–5138 (2009).

Schubert, S. W. et al. Relationships of crystallinity and response charges for enzymatic degradation of poly (ethylene terephthalate), PET. ChemSusChem 17, e202301752 (2024).

Falkenstein, P. et al. On the binding mode and molecular mechanism of enzymatic polyethylene terephthalate degradation. ACS Catal. 13, 6919–6933 (2023).

Jäckering, A. et al. From bulk to binding: decoding the entry of PET into hydrolase binding pockets. JACS Au 4, 4000–4012 (2024).

Wei, R. et al. Biocatalytic degradation effectivity of postconsumer polyethylene terephthalate packaging decided by their polymer microstructures. Adv. Sci. 6, 1900491 (2019).

Thomsen, T. B., Hunt, C. J. & Meyer, A. S. Affect of substrate crystallinity and glass transition temperature on enzymatic degradation of polyethylene terephthalate (PET). N. Biotechnol. 69, 28–35 (2022).

Zheng, M., Li, Y., Dong, W., Zhang, Q. & Wan, W. Hydrolase-catalyzed depolymerization mechanism towards crystalline and amorphous polyethylene terephthalate. ACS Maintain. Chem. Eng. 12, 10252–10259 (2024).

Patel, A. et al. Aqueous buffer solution-induced crystallization competes with enzymatic depolymerization of pre-treated post-consumer poly (ethylene terephthalate) waste. Polymer 285, 126370 (2023).

Tokiwa, Y. & Suzuki, T. Hydrolysis of polyesters by lipases. Nature 270, 76–78 (1977).

Buchholz, P. C. F. et al. Plastics degradation by hydrolytic enzymes: the plastics-active enzymes database — PAZy. Proteins 90, 1443–1456 (2022).

Butbunchu, N. & Pathom-Aree, W. Actinobacteria as promising candidate for polylactic acid kind bioplastic degradation. Entrance. Microbiol. 10, 2834 (2019).

Gambarini, V. et al. PlasticDB: a database of microorganisms and proteins linked to plastic biodegradation. Database 2022, 1–12 (2022).

Kleeberg, I., Welzel, Ok., Vandenheuvel, J., Müller, R. J. & Deckwer, W. D. Characterization of a brand new extracellular hydrolase from Thermobifida fusca degrading aliphatic-aromatic copolyesters. Biomacromolecules 6, 262–270 (2005).

Yang, Y. et al. Structural insights of poly(butylene adipate-co-terephthalate) depolymerases. Adv. Agrochem. 3, 126–132 (2024).

Alisch, M. et al. Biocatalytic modification of polyethylene terephthalate fibres by esterases from actinomycete isolates. Biocat. Biotransform. 22, 347–351 (2004).

Zimmermann, W. in Encyclopedia of Mycology Vol. 2 (ed. Zaragoza, O.) 650–661 (Elsevier, 2021).

Chen, I.-M. A. et al. IMG/M v.5.0: an built-in information administration and comparative evaluation system for microbial genomes and microbiomes. Nucleic Acids Res. 47, D666–D677 (2019).

Karunatillaka, I., Jaroszewski, L. & Godzik, A. Novel putative polyethylene terephthalate (PET) plastic degrading enzymes from the environmental metagenome. Proteins 90, 504–511 (2022).

Abid, U. et al. Analysis of enzymatic depolymerization of PET, PTT, and PBT polyesters. Biochem. Eng. J. 199, 109074 (2023).

Cui, Y. et al. Computational redesign of a PETase for plastic biodegradation underneath ambient situation by the GRAPE technique. ACS Catal. 11, 1340–1350 (2021).

Xia, Y. & Auclair, Ok. Mechanoenzymatic depolymerization of extremely crystalline polyethylene naphthalate underneath moist-solid situations. ACS Maintain. Chem. Eng. 12, 14832–14840 (2024).

Kawai, F. et al. Environment friendly depolymerization of polyethylene terephthalate (PET) and polyethylene furanoate by engineered PET hydrolase Cut190. AMB Expr. 12, 134 (2022).

Austin, H. P. et al. Characterization and engineering of a plastic-degrading fragrant polyesterase. Proc. Natl Acad. Sci. USA 115, E4350–E4357 (2018).

Kumar, V. et al. Environment friendly depolymerization of poly(ethylene 2,5-furanoate) utilizing polyester hydrolases. ACS Maintain. Chem. Eng. 12, 9658–9668 (2024).

Raczyńska, A., Góra, A. & André, I. An outline on polyurethane degrading enzymes. Biotechnol. Adv. 77, 108439 (2024).

Chen, C. C., Dai, L., Ma, L. & Guo, R. T. Enzymatic degradation of plant biomass and artificial polymers. Nat. Rev. Chem. 4, 114–126 (2020).

Danso, D. et al. New insights into the operate and international distribution of polyethylene terephthalate (PET)-degrading micro organism and enzymes in marine and terrestrial metagenomes. Appl. Environ. Microbiol. 84, e02773-17 (2018).

Makryniotis, Ok., Nikolaivits, E., Gkountela, C., Vouyiouka, S. & Topakas, E. Discovery of a polyesterase from Deinococcus maricopensis and comparability to the benchmark LCCICCG suggests excessive potential for semi-crystalline post-consumer PET degradation. J. Hazard. Mater. 455, 131574 (2023).

Distaso, M. A. et al. Thermophilic carboxylesterases from hydrothermal vents of the volcanic island of Ischia energetic on artificial and biobased polymers and mycotoxins. Appl. Environ. Microbiol. 89, e01704–e01722 (2023).

Perez-Garcia, P. et al. An archaeal lid-containing feruloyl esterase degrades polyethylene terephthalate. Commun. Chem. 6, 193 (2023).

Erickson, E. et al. Sourcing thermotolerant poly(ethylene terephthalate) hydrolase scaffolds from pure variety. Nat. Commun. 13, 7850 (2022).

Jahanshahi, D. A., Ariaeenejad, S. & Kavousi, Ok. A. metagenomic catalog for exploring the plastizymes panorama masking taxa, genes, and proteins. Sci. Rep. 13, 16029 (2023).

Ridley, R. S., Conrad, R. E., Lindner, B. G., Woo, S. & Konstantinidis, Ok. T. Potential routes of plastics biotransformation involving novel plastizymes revealed by international multi-omic evaluation of plastic related microbes. Sci. Rep. 14, 8798 (2024).

Jiang, R., Shang, L., Wang, R., Wang, D. & Wei, N. Machine studying based mostly prediction of enzymatic degradation of plastics utilizing encoded protein sequence and efficient characteristic illustration. Environ. Sci. Technol. Lett. 10, 557–564 (2023).

Jiang, R., Yue, Z., Shang, L., Wang, D. & Wei, N. PEZy-miner: a man-made intelligence pushed strategy for the invention of plastic-degrading enzyme candidates. Metab. Eng. Commun. 19, e00248 (2024).

Wei, R., Oeser, T. & Zimmermann, W. Artificial polyester-hydrolyzing enzymes from thermophilic actinomycetes. Adv. Appl. Microbiol. 89, 267–305.

Castro, A. M. et al. Excessive-fold enchancment of varied post-consumer poly(ethylene terephthalate) (PET) packages hydrolysis utilizing Humicola insolens cutinase as a single biocatalyst. Course of Biochem. 81, 85–91 (2019).

Yang, S. et al. A low molecular mass cutinase of Thielavia terrestris effectively hydrolyzes poly(esters). J. Ind. Microbiol. Biotechnol. 40, 217–226 (2013).

Brinch-Pedersen, W. et al. Discovery and floor cost engineering of fungal cutinases for enhanced exercise on poly(ethylene terephthalate). ACS Maintain. Chem. Eng. 12, 7329–7337 (2024).

Lee, S. H. et al. Characterization and engineering of a fungal poly(ethylene terephthalate) hydrolysing enzyme from Aspergillus fumigatiaffinis. ACS Catal. 14, 4108–4116 (2024).

Uekert, T. et al. Technical, financial, and environmental comparability of closed-loop recycling applied sciences for widespread plastics. ACS Maintain. Chem. Eng. 11, 965–978 (2023).

Bollinger, A. et al. A novel polyester hydrolase from the marine bacterium Pseudomonas aestusnigri — structural and useful insights. Entrance. Microbiol. 11, 114 (2020).

Zhou, X., Zhou, X., Xu, Z., Zhang, M. & Zhu, H. Characterization and engineering of plastic-degrading polyesterases jmPE13 and jmPE14 from Pseudomonas bacterium. Entrance. Bioeng. Biotechnol. 12, 1349010 (2024).

Sagong, H. Y. et al. Implications for the PET decomposition mechanism by similarity and dissimilarity between PETases from Rhizobacter gummiphilus and Ideonella sakaiensis. J. Hazard. Mater. 416, 126075 (2021).

Blázquez-Sánchez, P. et al. Antarctic polyester hydrolases degrade aliphatic and fragrant polyesters at average temperatures. Appl. Environ. Microbiol. 88, e01842–21 (2022).

Blázquez-Sánchez, P. et al. Engineering the catalytic exercise of an Antarctic PET-degrading enzyme by loop trade. Protein Sci. 32, e4757 (2023).

Nikolaivits, E. et al. A polyesterase from the Antarctic bacterium Moraxella sp. degrades extremely crystalline artificial polymers. J. Hazard. Mater. 434, 128900 (2022).

Hellesnes, Ok. N., Vijayaraj, S., Fojan, P., Petersen, E. & Courtade, G. Biochemical characterization and NMR examine of a PET-hydrolysing cutinase from Fusarium solani pisi. Biochemistry 62, 1369–1375 (2023).

Nimchua, T., Punnapayak, H. & Zimmermann, W. Comparability of the hydrolysis of polyethylene terephthalate fibres by a hydrolase from Fusarium oxysporum LCH I and Fusarium solani f. sp. pisi. Biotechnol. J. 2, 361–364 (2007).

Dimarogona, M. et al. Structural and useful research of a Fusarium oxysporum cutinase with polyethylene terephthalate modification potential. Biochim. Biophys. Acta Gen. Subj. 1850, 2308–2317 (2015).

Eiamthong, B. et al. Discovery and genetic code growth of a polyethylene terephthalate (PET) hydrolase from the human saliva metagenome for the degradation and bio-functionalization of PET. Angew. Chem. 61, e202203061 (2022).

Zhou, H. et al. Polyethylene terephthalate hydrolases in human intestine microbiota and their implications for human well being. Microorganisms 12, 138 (2024).

Oeser, T., Wei, R., Baumgarten, T., Billig, S., Föllner, C. & Zimmermann, W. Excessive degree expression of a hydrophobic poly(ethylene terephthalate)-hydrolysing carboxylesterase from Thermobifida fusca KW3 in Escherichia coli BL21(DE3). J. Biotechnol. 146, 100–104 (2010).

Billig, S., Oeser, T., Birkemeyer, C. & Zimmermann, W. Hydrolysis of cyclic poly(ethylene terephthalate) trimers by a carboxylesterase from Thermobifida fusca KW3. Appl. Microbiol. Biotechnol. 87, 1753–1764 (2010).

von Haugwitz, G. et al. Structural insights into (tere)phthalate-ester hydrolysis by a carboxylesterase and its position in selling PET depolymerization. ACS Catal. 12, 15259–15270 (2022).

Aer, Z. et al. Optimization of polyethylene terephthalate biodegradation utilizing a self-assembled multi-enzyme cascade technique. J. Hazard. Mater. 476, 134887 (2024).

Leveson-Gower, R. B., Mayer, C. & Roelfes, G. The significance of catalytic promiscuity for enzyme design and evolution. Nat. Rev. Chem. 3, 687–705 (2019).

Martinez, C., De Geus, P., Lauwereys, M., Matthyssens, G. & Cambillau, C. Fusarium solani cutinase is a lipolytic enzyme with a catalytic serine accessible to solvent. Nature 356, 615–618 (1992).

Kold, D. et al. Thermodynamic and structural investigation of the particular SDS binding of Humicola insolens cutinase. Protein Sci. 23, 1023–1035 (2014).

Kitadokoro, Ok. et al. Crystal construction of cutinase Est119 from Thermobifida alba AHK119 that may degrade modified polyethylene terephthalate at 1.76 Å decision. Polym. Degrad. Stab. 97, 771–775 (2012).

Roth, C. et al. Structural and useful research on a thermostable polyethylene terephthalate degrading hydrolase from Thermobifida fusca. Appl. Microbiol. Biotechnol. 98, 7815–7823 (2014).

Sulaiman, S., You, D.-J., Kanaya, E., Koga, Y. & Kanaya, S. Crystal construction and thermodynamic and kinetic stability of metagenome-derived LC-compost. Biochemistry 53, 1858–1869 (2014).

Meng, S. et al. Deep studying guided enzyme engineering of Thermobifida fusca cutinase for elevated PET T depolymerization. Chin. J. Catal. 50, 229–238 (2023).

Li, Q. et al. Computational design of a cutinase for plastic biodegradation by mining molecular dynamics simulations trajectories. Comput. Struct. Biotechnol. J. 20, 459–470 (2022).

Ding, Z. et al. Rational redesign of thermophilic PET hydrolase LCCICCG to reinforce hydrolysis of excessive crystallinity polyethylene terephthalates. J. Hazard. Mater. 453, 131386 (2023).

Cui, Y. et al. Computational redesign of a hydrolase for almost full PET depolymerization at industrially related high-solids loading. Nat. Commun. 15, 1417 (2024).

Chen, S. et al. Biochemical characterization of the cutinases from Thermobifida fusca. J. Mol. Catal. B 63, 121–127 (2010).

Wei, R. et al. Engineered bacterial polyester hydrolases effectively degrade polyethylene terephthalate as a consequence of relieved product inhibition. Biotechnol. Bioeng. 113, 1658–1665 (2016).

Then, J. et al. Ca2+ and Mg2+ binding website engineering will increase the degradation of polyethylene terephthalate movies by polyester hydrolase from Thermobifida fusca. Biotechnol. J. 10, 592–598 (2015).

Then, J. et al. A disulfide bridge within the calcium binding website of a polyester hydrolase will increase its thermal stability and exercise in opposition to PET. FEBS Open Bio 6, 425–432 (2016).

Acero, E. H. et al. Floor engineering of a cutinase from Thermobifida cellulosilytica for improved polyester hydrolysis. Biotechnol. Bioeng. 110, 2581–2590 (2013).

Mrigwani, A. et al. Rational mutagenesis of Thermobifida fusca cutinase to modulate the enzymatic degradation of polyethylene terephthalate. Biotechnol. Bioeng. 120, 674–686 (2023).

Chen, X.-Q. et al. Directional-path modification technique enhances PET hydrolase catalysis of plastic degradation. J. Hazard. Mater. 433, 128816 (2022).

Silva, C. et al. Engineered Thermobifida fusca cutinase with elevated exercise on polyester substrates. Biotechnol. J. 6, 1230–1239 (2011).

Zhang, Z. et al. Depolymerization of post-consumer PET bottles with engineered cutinase 1 from Thermobifida cellulosilytica. Inexperienced Chem. 24, 5998 (2022).

Hong, H. et al. Discovery and rational engineering of PET hydrolase with each mesophilic and thermophilic PET hydrolase properties. Nat. Commun. 14, 4556 (2023).

Zeng, W. et al. Substrate-binding mode of a thermophilic PET hydrolase and engineering the enzyme to reinforce the hydrolytic efficacy. ACS Catal. 12, 3033–3040 (2022).

Sahihi, M. et al. Probing enzymatic PET degradation: molecular dynamics evaluation of cutinase adsorption and stability. J. Chem. Inf. Mannequin. 64, 4112–4120 (2024).

Pirillo, V., Orlando, M., Battaglia, C., Pollegioni, L. & Molla, G. Environment friendly polyethylene terephthalate degradation at average temperature: a protein engineering examine of LC-cutinase highlights the important thing position of residue 243. FEBS J. 290, 3185–3202 (2023).

Fritzsche, S., Tischer, F., Peukert, W. & Castiglione, Ok. You get what you display screen for: a benchmark evaluation of leaf department compost cutinase variants for polyethylene terephthalate (PET) degradation. React. Chem. Eng. 8, 2156–2169 (2023).

Cribari, M. A. et al. Ultrahigh-throughput directed evolution of polymer-degrading enzymes utilizing yeast show. J. Am. Chem. Soc. 145, 27380–27389 (2023).

Zheng, Y. et al. Dynamic docking-assisted engineering of hydrolases for environment friendly PET depolymerization. ACS Catal. 14, 3627–3639 (2024).

Britton, D. et al. Protein-engineered leaf and department compost cutinase variants utilizing computational screening and IsPETase homology. Catal. Immediately 433, 114659 (2024).

Guo, C., Zhang, L.-Q. & Jiang, W. Biodegrading plastics with an artificial non-biodegradable enzyme. Chem 9, 363–376 (2023).

Xi, X. et al. Secretory expression in Bacillus subtilis and biochemical characterization of a extremely thermostable polyethylene terephthalate hydrolase from bacterium HR29. Enzyme Microb. Technol. 143, 109715 (2021).

Feng, S., Xue, M., Xie, F., Zhao, H. & Xue, Y. J. Characterization of Thermotoga maritima esterase able to hydrolysing bis(2-hydroxyethyl) terephthalate. Agric. Meals Chem. 72, 12045–12056 (2024).

Richter, P. Ok. et al. Construction and performance of the metagenomic plastic-degrading polyester hydrolase PHL7 sure to its product. Nat. Commun. 14, 1905 (2023).

Pfaff, L. et al. A number of substrate binding mode-guided engineering of a thermophilic PET hydrolase. ACS Catal. 12, 9790–9800 (2022).

Nakamura, A., Kobayashi, N., Koga, N. & Iino, R. Constructive cost introduction on the floor of thermostabilized PET hydrolase facilitates PET binding and degradation. ACS Catal. 11, 8550–8564 (2021).

Ercolano, C. et al. Biochemical characterisation of Sis: a definite thermophilic PETase with enhanced nanoPET substrate hydrolysis and thermal stability. Int. J. Mol. Sci. 25, 8120 (2024).

Fecker, T. et al. Energetic website flexibility as an indicator for environment friendly PET degradation by I. sakaiensis PETase. Biophys. J. 114, 1302–1312 (2018).

Chen, C. C. et al. Common options to reinforce enzymatic exercise of poly(ethylene terephthalate) hydrolysis. Nat. Catal. 4, 425–430 (2021).

Berselli, A., Menziani, M. C. & Muniz-Miranda, F. Construction and energetics of PET-hydrolyzing enzyme complexes: a scientific comparability from molecular dynamics simulations. J. Chem. Inf. Mannequin. 64, 8236–8257 (2024).

Oda, Ok. & Wlodawer, A. Growth of enzyme-based approaches for recycling PET on an industrial scale. Biochemistry 63, 369–401 (2024).

Son, H. et al. Rational protein engineering of thermo-stable PETase from Ideonella sakaiensis for extremely environment friendly PET degradation. ACS Catal. 9, 3519–3526 (2019).

Schreiber, S., Gercke, D., Lenz, F. & Jose, J. Utility of an alchemical free power technique for the prediction of thermostable DuraPETase variants. Appl. Microbiol. Biotechnol. 108, 305 (2024).

García-Meseguer, R., Ortí, E., Tuñón, I., Ruiz-Pernía, J. & Aragó, J. Insights into the enhancement of the poly(ethylene terephthalate) degradation by FAST-PETase from computational modelling. J. Am. Chem. Soc. 145, 19243–19255 (2023).

Qu, Z. & Solar, Y. Laptop-aided site-specific PEGylation of PET hydrolases for enhanced PET degradation. ACS Appl. Mater. Interfaces 16, 55463–55477 (2024).

Joho, Y. et al. Enhancing PET degrading enzymes: a combinatory strategy. ChemBioChem 25, e202400084 (2024).

Bell, E. L. et al. Directed evolution of an environment friendly and thermostable PET depolymerase. Nat. Catal. 5, 673–681 (2022).

Shi, L. et al. Full depolymerization of PET wastes by an developed PET hydrolase from directed evolution. Angew. Chem. 135, e202218390 (2023).

Kawai, F., Iizuka, R. & Kawabata, T. Engineered polyethylene terephthalate hydrolases: views and limits. Appl. Microbiol. Biotechnol. 108, 404 (2024).

Zurier, H. S. & Goddard, J. M. Directed Immobilization of PETase on mesoporous silica allows sustained depolymerase exercise in artificial wastewater situations. ACS Appl. Bio Mater. 5, 4981–4992 (2022).

Zhu, B., Ye, Q., Website positioning, Y. & Wei, N. Enzymatic degradation of polyethylene terephthalate plastics by bacterial curli show PETase. Environ. Sci. Technol. Lett. 9, 650–657 (2022).

Yoon, M.-Y., Kellis, J. & Poulose, A. J. Enzymatic modification of polyester. AATCC Rev. 2, 33–36 (2002).

Mccloskey, S. G. & Soar, J. M. Bio-polishing of polyester and polyester/cotton cloth. Textual content. Res. J. 75, 480–484 (2005).

Supplies Market Report 2024 (Textile Alternate, 2024).

Bianchi, S. et al. Alternatives and limitations in recycling fossil polymers from textiles. Macromol 3, 120–148 (2023).

Kaabel, S. et al. Stable‐state enzymatic hydrolysis of combined PET/cotton textiles. ChemSusChem 16, e202201613 (2022).

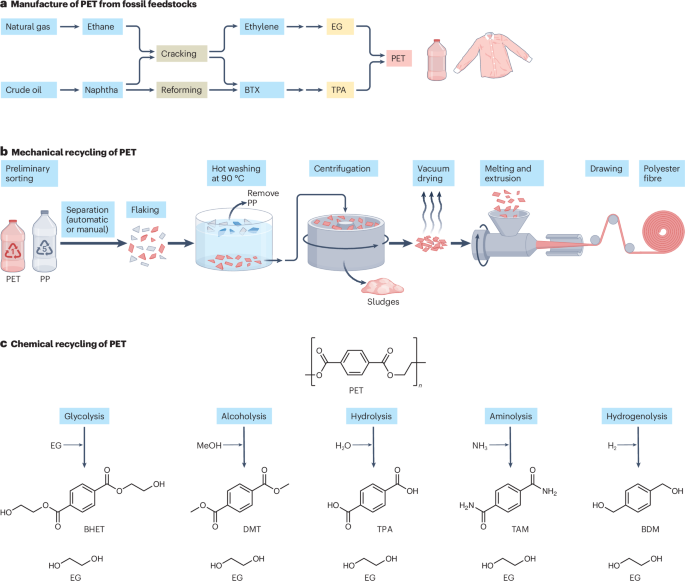

McNeeley, A. & Liu, Y. A. Evaluation of PET depolymerization processes for round financial system. 1. Thermodynamics, chemistry, purification, and course of design. Ind. Eng. Chem. Res. 63, 3355–3399 (2024).

Barth, M. et al. A twin enzyme system composed of a polyester hydrolase and a carboxylesterase enhances the biocatalytic degradation of polyethylene terephthalate movies. Biotechnol. J. 11, 1082–1087 (2016).

Carniel, A., Valoni, É., Nicomedes, J., Gomes, A. C. & Castro, A. M. Lipase from Candida antarctica (CALB) and cutinase from Humicola insolens act synergistically for PET hydrolysis to terephthalic acid. Course of Biochem. 59, 84–90 (2017).

Knott, B. C. et al. Characterization and engineering of a two-enzyme system for plastics depolymerization. Proc. Natl Acad. Sci. USA 117, 25476–25485 (2020).

Lu, D. et al. Twin-enzyme-cascade catalysis for PET biodegradation based mostly on a variable-temperature program. Catalysts 14, 543 (2024).

Graham, R. et al. The position of binding modules in enzymatic poly(ethylene terephthalate) hydrolysis at high-solids loadings. Chem. Catal. 2, 2644–2657 (2022).

Arnal, G. et al. Evaluation of 4 engineered PET degrading enzymes contemplating large-scale industrial purposes. ACS Catal. 13, 13156–13166 (2023).

Roosen, M. et al. Detailed evaluation of the composition of chosen plastic packaging waste merchandise and its implications for mechanical and thermochemical recycling. Environ. Sci. Technol. 54, 13282–13293 (2020).

Pučnik, R. et al. A waste separation system based mostly on sensor know-how and deep studying: a easy strategy utilized to a case examine of plastic packaging waste. J. Clear. Prod. 450, 141762 (2024).

Tamizhdurai, P. et al. A state-of-the-art evaluation of multilayer packaging recycling: challenges, options, and outlook. J. Clear. Prod. 447, 141403 (2024).

Gamerith, C. et al. Enzymatic restoration of polyester constructing blocks from polymer blends. Course of Biochem. 59, 58–64 (2017).

Araujo, J. A. et al. Biotechnological mannequin for ubiquitous combined petroleum- and bio-based plastics degradation and upcycling into bacterial nanocellulose. J. Clear. Prod. 443, 141025 (2024).

Patel, A. et al. Soften processing pretreatment results on enzymatic depolymerization of poly(ethylene terephthalate). ACS Maintain. Chem. Eng. 10, 13619–13628 (2022).

Uekert, T. et al. Life cycle evaluation of enzymatic poly(ethylene terephthalate) recycling. Inexperienced Chem. 24, 6531–6543 (2022).

Patel, A. et al. Enzymatic depolymerization of polyester: foaming as a pretreatment to extend particular floor space. J. Appl. Polym. Sci. 141, e56177 (2024).

Banks, A. M. et al. Degradation of PET plastic with engineered environmental micro organism. Preprint at bioRxiv https://doi.org/10.1101/2024.09.24.614569 (2024).

Giraldo-Narcizo, S., Guenani, N., Sánchez-Pérez, A. M. & Guerrero, A. Accelerated polyethylene terephthalate (PET) enzymatic degradation by room temperature alkali pre-treatment for lowered polymer crystallinity. ChemBioChem 24, e202200503 (2023).

Kaabel, S. et al. Enzymatic depolymerization of extremely crystalline polyethylene terephthalate enabled in moist-solid response mixtures. Proc. Natl Acad. Sci. USA 118, e2026452118 (2021).

Brizendine, R. Ok. et al. Particle dimension discount of poly(ethylene terephthalate) will increase the speed of enzymatic depolymerization however doesn’t enhance the general conversion extent. ACS Maintain. Chem. Eng. 10, 9131–9140 (2022).

Guo, B. et al. Quick depolymerization of PET bottle mediated by microwave pre-treatment and an engineered PETase. ChemSusChem 16, e202300742 (2023).

Attallah, O. A., Taxeidis, G., Chee, B., Topakas, E. & Fournet, B. M. Mechanochemical and mechanobiological recycling of postconsumer polyethylene terephthalate (PET) plastics underneath microwave irradiation: a comparative examine. J. Polym. Res. 30, 354 (2023).

Fohler, L., Leibetseder, L., Cserjan-Puschmann, M. & Striedner, G. Manufacturing of the extremely energetic thermophile PETases PHL7 and PHL7mut3 utilizing Escherichia coli. Microb. Cell Reality. 23, 272 (2024).

Li, J.-X., Zhao, L.-M., Wu, R.-J., Zheng, Z.-J. & Zhang, R.-J. Excessive-level overproduction of Thermobifida enzyme in Streptomyces lividans utilizing a novel expression vector. Int. J. Mol. Sci. 14, 18629–18639 (2013).

Zhou, Y. et al. Growth of a novel ‘4E’ polyethylene terephthalate bio-recycling course of with the potential for industrial utility: environment friendly, economical, energy-saving, and eco-friendly. Bioresour. Technol. 391, 129913 (2024).

Chen, C.-C. et al. Full decomposition of poly(ethylene terephthalate) by crude PET hydrolytic enzyme produced in Pichia pastoris. Chem. Eng. J. 481, 148418 (2024).

Deng, B. et al. Bettering the exercise and thermostability of PETase from Ideonella sakaiensis by modulating its post-translational glycan modification. Commun. Biol. 6, 39 (2023).

Quartinello, F. et al. Synergistic chemo-enzymatic hydrolysis of poly(ethylene terephthalate) from textile waste. Microb. Biotechnol. 10, 1376–1383 (2017).

Li, H. et al. Increasing plastics recycling applied sciences: chemical facets, know-how standing and challenges. Inexperienced Chem. 24, 8899 (2022).

Payne, J., McKeown, P. & Jones, M. D. A round financial system strategy to plastic waste. Polym. Degrad. Stab. 165, 170–181 (2019).

Youngpreda, A. et al. Optimization of poly(dl-lactic acid) degradation and analysis of organic re-polymerization. J. Polym. Environ. 25, 1131–1139 (2017).

Huang, Q., Hiyama, M., Kabe, T., Kimura, S. & Iwata, T. Enzymatic self-biodegradation of poly(l-lactic acid) movies by embedded heat-treated and immobilized proteinase Ok. Biomacromolecules 21, 3301–3307 (2020).

DelRe, C. et al. Close to-complete depolymerization of polyesters with nano-dispersed enzymes. Nature 592, 558–563 (2021).

Arunrattanamook, N. et al. Identification of a plastic-degrading enzyme from Cryptococcus nemorosus and its use in self-degradable plastics. Appl. Microbiol. Biotechnol. 107, 7439–7450 (2023).

Guicherd, M. et al. An engineered enzyme embedded into PLA to make self-biodegradable plastic. Nature 631, 884–890 (2024).

de Jong, E., Visser, H. A., Dias, A. S., Harvey, C. & Gruter, G.-J. M. The highway to convey FDCA and PEF to the market. Polymers 14, 943 (2022).

Raczyńska, A., Góra, A. & André, I. An outline on polyurethane-degrading enzymes. Biotechnol. Adv. 70, 108439 (2024).

Rossignolo, G., Malucelli, G. & Lorenzetti, A. Recycling of polyurethanes: the place we’re and the place we’re going. Inexperienced Chem. 26, 1132 (2024).

Liu, B. et al. Alternatives in closed-loop molecular recycling of end-of-life polyurethane. ACS Maintain. Chem. Eng. 11, 6114–6128 (2023).

Magnin, A. et al. Enzymatic recycling of thermoplastic polyurethanes: synergistic impact of an esterase and an amidase and restoration of constructing blocks. Waste Manag. 85, 141–150 (2019).

Branson, Y. et al. Urethanases for the enzymatic hydrolysis of low molecular weight carbamates and the recycling of polyurethanes. Angew. Chem. Int. Ed. Engl. 62, e202216220 (2023).

Xin, Ok. et al. Depolymerization of the polyester–polyurethane by amidase GatA250 and enhancing the manufacturing of 4,4′-methylenedianiline with cutinase LCC. Biotechnol. J. 19, e2300723 (2024).

Gallorini, R. et al. Subcritical hydrothermal liquefaction as a pretreatment for enzymatic degradation of polyurethane. ACS Omega 42, 37757–37763 (2022).